As the number of COVID-19 cases continue to rise across the country, most Canadians remain homebound—doing their part to flatten the curve—but wanting to help from the confines of their couch.

However, Whistler resident John Ford didn't have to go far when inspiration struck.

After a longstanding fascination with 3D printing, Ford purchased his own printer about eight months ago, mostly to "play around with" and use to craft mini-action figures for games like Dungeons and Dragons. "It's kind of my nerd side," he said with a laugh.

The printers are no longer the exorbitantly expensive, complicated contraptions they were when they first made their way onto the market, he explained.

Nowadays, "you can pretty much pay the same price that you're paying for a paper printer."

So, when he heard about frontline health care workers facing shortages of personal protective equipment amid the ongoing coronavirus pandemic, he figured his printer could be put to use.

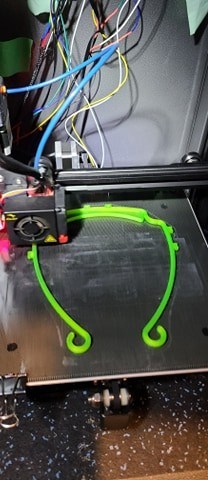

"There's lots of designs online," Ford explained. He found a fairly simple one for a full-face shield from Swedish-based 3DVerkstan, downloaded the design, and "remixed" it, to strengthen a few parts of the visor.

"I started printing it, and took a sample of it to the Whistler Health [Care Centre], and they thought it was fantastic and asked for more," Ford said.

(The design he chose had already been tested and approved for medical use, he added).

While the 3D printer crafts the halo-style visors, the shields themselves are just repurposed overhead transparencies—think the acetate sheets your high school teachers used to write on overhead projectors with.

The design's template is set up to allow for the use of a standard three-hole punch, Ford explained. Once holes are punched into the plastic sheets, the makeshift masks are easily clipped onto the plastic visors' pegs.

One benefit to the design is that it allows health care workers to easily remove and swap out the plastic mask if it becomes dirty or contaminated, without the wearer having to "replace the whole shield like you have to do with the traditional ones," Ford added.

Each visor takes about an hour to print. So far, he's printed 24, in a variety of colours.

"I just saw the need and thought I'd see what I could do," he said.

While local health care workers aren't in immediate need of the shields quite yet, they are anticipating a need for them "within a couple of weeks," Ford added.

After reaching out on the local Facebook group to see if anyone in town had plastic sheets to spare-the ones he could order online wouldn't be delivered until April-Whistler Hardware stepped up and provided 35 sheets. Other locals who said they are also 3D printing the protective devices responded to Ford's post with the same request for spare transparencies, as well.

"People want to help, but you're being told to stay home, and it's finding those things to do from home," Ford said.

When it comes to 3D printing medical apparatus, "there's a bunch of things that are popping up online now," he continued, citing some designers who are printing in-demand, lifesaving equipment like ventilator valves.

"I haven't been able to really find those files yet to print. But, as this [pandemic] goes on a little bit longer and people are realizing that it's real, more of these opportunities are arising and I think it's going to become a lot more normal to have a [design] file out there, and get the offering of the public and the people who are willing to help to be able to pitch in and help."